A karkashin yanayi na rigidity, an yi amfani da zurfin yanke mafi girma don roughing don rage yawan wucewa da inganta yawan aiki na aikin;don kammalawa, ana amfani da ƙaramin zurfin yanke gabaɗaya don samun ingancin ƙasa mafi girma.Yana shafar daidaiton mashin ɗin ƙarshe da ingantaccen aikin injin, ban da dalilai na kayan aikin injin CNC da kansa, ya kamata kuma ya haɗa da saitunan machining madaidaiciya, zaɓin kayan aiki da shigarwa daidai, zaɓi mai dacewa na yankan adadin, ƙwarewar shirye-shirye, da sauri. kula da daidaiton girma.m la'akari.

1. Fasahar shirye-shirye

Shirye-shiryen NC shine mafi mahimmancin aikin NC machining.Ribobi da fursunoni na shirin mashin kayan aikin kai tsaye suna shafar daidaiton injin na ƙarshe da ingancin injin na'urar.Yana iya farawa daga bangarori da yawa, kamar amfani da wayo na shirye-shirye na asali, rage yawan kurakurai na tsarin CNC, da sassauƙan amfani da manyan shirye-shirye da shirye-shirye.

1. M amfani da babban shirin da subprogram

A cikin sarrafa hadaddun gyare-gyare, ana sarrafa shi gaba ɗaya a cikin nau'i na nau'i ɗaya da guda ɗaya.Idan akwai sifofi iri ɗaya a kan mold, ya kamata a yi amfani da alaƙar da ke tsakanin babban shirin da ƙaramin shiri cikin sassauƙa, kuma a sake kiran ƙaramin shirin a cikin babban shirin har sai an gama sarrafa shi.Ba wai kawai zai iya tabbatar da daidaiton ma'aunin sarrafawa ba amma har ma inganta ingantaccen sarrafa shi.

2. Rage kuskuren tarawa na tsarin CNC

Gabaɗaya, ana amfani da hanyar haɓakawa don tsara aikin aikin, wanda ya dogara akan batun da ya gabata.Ta wannan hanyar, ci gaba da aiwatar da shirye-shiryen sassa da yawa ba makawa zai haifar da wani kuskure mai tarin yawa.Don haka, yi ƙoƙarin yin amfani da cikakken shirye-shiryen lokacin shirye-shirye, ta yadda kowane ɓangaren shirin ya dogara da aikin aikin.Asalin shine ma'auni, ta yadda za'a iya rage yawan kuskuren tsarin CNC kuma ana iya tabbatar da daidaiton mashin ɗin.

Ana amfani da daidaiton injina galibi don samar da samfura, kuma daidaiton injina da kuskuren mashin ɗin kalmomi ne da ake amfani da su don kimanta ma'auni na geometric na saman da aka kera.Koyaya, ainihin ma'aunin da aka samu ta kowace hanyar injin ba za ta zama cikakke cikakke ba.Daga aikin sashin, muddin kuskuren injin ɗin yana cikin kewayon haƙuri da ake buƙata ta ɓangaren zane, ana la'akari da cewa an tabbatar da daidaiton injin ɗin.

Daidaiton mashin ɗin yana nufin ainihin sigogin lissafi (girma, siffa da matsayi) na ɓangaren bayan aikin injiniya.Bambanci tsakanin su ana kiran kuskuren machining.Girman kuskuren mashin ɗin yana nuna matakin daidaiton mashin ɗin.Mafi girman kuskuren, ƙananan daidaiton injina, kuma ƙaramin kuskuren, mafi girman daidaiton injin.Mai zuwa shine taƙaitaccen gabatarwar ga hanyoyin don haɓaka daidaiton injina na kayan aiki:

1. Daidaita tsarin tsari

1): Ana daidaita hanyar yanke gwaji ta hanyar yanke gwaji - auna girman - daidaita adadin cizon wuka na kayan aiki - yanke ta hanyar yanke - sake gwada yankewa, da sauransu har sai girman da ake so ya kai.Wannan hanyar tana da ƙarancin ƙarancin samarwa kuma ana amfani da ita galibi don ƙaramin tsari guda ɗaya.

2): Hanyar daidaitawa ta sami girman da ake buƙata ta hanyar daidaitawa matsayi na dangi na kayan aikin inji, kayan aiki, kayan aiki da kayan aiki.Wannan hanya tana da babban yawan aiki kuma ana amfani da ita don samar da yawa.

2. Rage kuskuren kayan aikin injin

--Ya kamata a inganta daidaiton jujjuyawar abin ɗagawa

①Zaɓi madaidaicin mirgina bearings

②Amfani da madaidaicin madaidaicin matsi mai ƙarfi mai ƙarfi

③Amfani da madaidaicin madaidaicin ruwa

--Inganta daidaito na na'urorin haɗi tare da bearings

① Inganta daidaiton injina na ramukan tallafin akwatin da mujallu na dunƙule

② Haɓaka daidaiton mashin ɗin na mating surface tare da ɗaukar hoto

③ Auna da daidaita kewayon runout na radial na sassan da suka dace don yin ramuwa ko biya da kuskure

--Da kyau a fara loda abin birgima

① Zai iya kawar da gibin

②Ƙara taurin kai

③ Homogenization na birgima kashi kuskure

--Ba a ganin daidaiton jujjuyawar sandal akan kayan aikin

3. Rage kuskuren watsawa na sarkar watsawa

(1) Yawan sassan watsawa ƙananan ne, sarkar watsawa gajere ne, kuma daidaitaccen watsawa yana da yawa

(2) Yin amfani da watsawar ragewa muhimmiyar ka'ida ce don tabbatar da daidaiton watsawa, kuma mafi kusancin nau'in watsawa ya kasance zuwa ƙarshe, ƙarami ya kamata ya kasance.

(3) Madaidaicin yanki na ƙarshen yakamata ya zama mafi girma fiye da na sauran sassan watsawa

Na hudu, rage kayan aiki

(1) Dole ne a sake gyara kayan aiki kafin girman girman kayan aiki ya kai matakin lalacewa mai sauri

(2) Zaɓi man yankan na musamman don cikar man shafawa

(3) Kayan kayan aiki ya kamata ya dace da bukatun tsari

5. Rage damuwa da lalata tsarin tsari

(1) Inganta tsaurin tsarin, musamman ma ƙaƙƙarfan raƙuman alaƙa a cikin tsarin tsari.

(2) Rage kaya da canje-canjensa

6. Rage nakasar thermal na tsarin tsari

(1) Rage samar da zafi na tushen zafi da keɓe tushen zafi

(2) Ma'aunin zafin filin

(3) Ɗauki madaidaicin tsarin ɓangaren kayan aikin injin da ma'aunin taro

(4) Haɗa don cimma daidaiton canja wurin zafi

(5) Sarrafa yanayin zafi

Bakwai, rage saura damuwa

(1) Ƙara tsarin maganin zafi don kawar da damuwa na ciki;

(2) Daidaita tsarin tsarin fasaha.

Abin da ke sama shine hanyar da za a rage kuskuren aikin aikin, kuma tsarin da ya dace na tsari zai iya inganta daidaitattun kayan aiki.

Ƙarin bayani game da wannan tushen rubutuSource da ake buƙata don ƙarin bayanin fassarar

Aika martani

Dabarun gefe

Tarihi

Ajiye

Taimakawa

2. Madaidaicin saitin hanyoyin sarrafawa

Madaidaicin saitin hanyar sarrafawa da tsarin sarrafawa shine muhimmin tushe don inganta shirin sarrafa kayan aiki.Ana iya la'akari da shi daga yanayin hanyar mashin din da kuma hanyar ciyarwa.

Lokacin aiwatar da aikin niƙa CNC na kayan aikin, ya zama dole don zaɓar hanyar ciyar da ta dace bisa ga buƙatun fasaha na kayan aikin don tabbatar da daidaiton yankan da ingancin sarrafa kayan aikin.A lokacin da ake niƙa gefen kwane-kwane na aikin jirgin sama, ya kamata a shirya hanyoyin da aka yanke da kuma yanke kayan aikin.Yi ƙoƙarin yanke ciki da waje tare da layin tsawo na kwandon kwandon shara don guje wa alamun wuƙa a mahadar.A lokaci guda, a cikin aikin niƙa, ƙaddamar da niƙa ko sama ya kamata a zaɓa bisa ga yanayin aikin aikin.

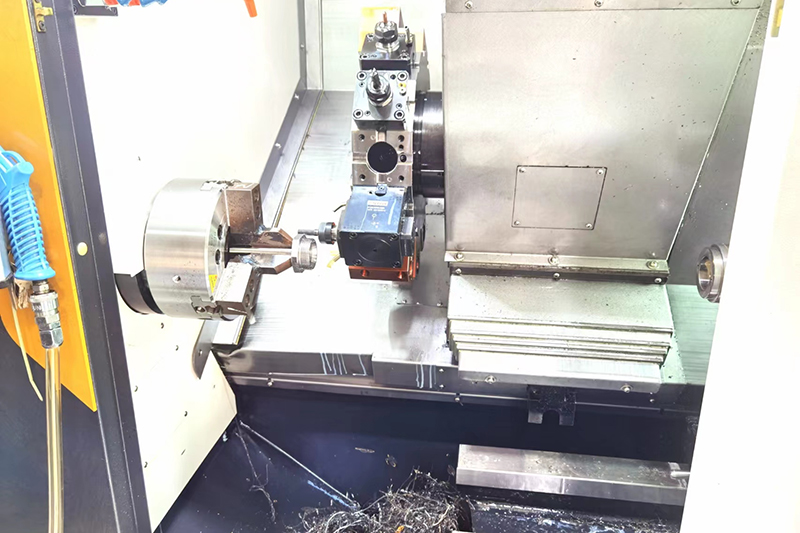

3. Zaɓin kayan aiki da shigarwa daidai

Ko yana CNC machining ko talakawa machining, da kayan aiki kai tsaye aiki a kan workpiece, don haka ta zabi da shigarwa su ne mafi muhimmanci dalilai ga machining daidaito da kuma surface ingancin workpiece.Musamman lokacin da aka sarrafa kayan aikin a cibiyar injin CNC, ana adana kayan aikin a cikin mujallar kayan aiki a gaba, kuma da zarar an fara aiki, ba za a iya maye gurbin su yadda ake so ba.Sabili da haka, ka'idodin zaɓin kayan aiki na gabaɗaya shine: sauƙi mai sauƙi da daidaitawa, tsauri mai kyau, tsayin daka da daidaito.

4. M zabi na yankan adadin

Ƙaddamar da adadin yankan shine muhimmin ɓangare na tsarin aikin CNC.Girmansa shine muhimmin ma'auni na babban motsi da motsin abinci na kayan aikin injin, kuma yana da tasiri mai mahimmanci akan daidaiton kayan aiki, ingantaccen kayan aiki da kayan aiki na kayan aiki.Zaɓin adadin yankan ya haɗa da saurin yankewa, adadin yanke baya da adadin ciyarwa.Ka'idodin zaɓi na asali shine: lokacin da rigidity ya ba da izini, ana amfani da zurfin yanke mafi girma don roughing don rage adadin wucewa da haɓaka yawan aiki na aikin;ƙaramin zurfin yanke gabaɗaya ana amfani da shi don kammalawa don samun ingancin saman mafi girma.

Lokacin aikawa: Satumba-26-2022